Cut downtime. Boost safety. Outperform idlers.

The only conveyor belt support that eliminates moving parts — for longer life, safer operation, and higher ROI.

Better Conveyor ROI. Safer Operations.

Proven in the Harshest Environments

The End of Reactive Conveyor Maintenance

Traditional idlers are a primary source of operational instability. Seized bearings and roller failures lead to frequent unplanned shutdowns, excessive labor hours for changeouts, and increased safety exposure for maintenance teams.

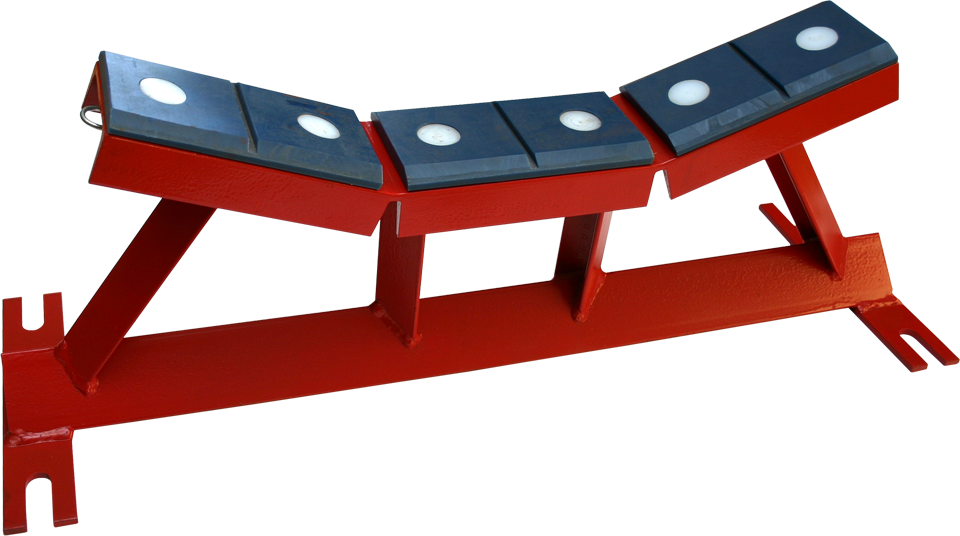

The NovaGlide Slidler eliminates these failure modes by replacing rotating components with a fixed, durable sliding surface that lasts years longer than idlers.

By removing bearings and moving parts entirely, you eliminate the root cause of idler-related downtime and maintenance backlog.

Strategic Advantages for Maintenance Teams

Transitioning to Slidler technology allows your team to shift from emergency repairs to a proactive maintenance model.

Proven Economic Impact

Typical installations deliver a 2–5× return on investment through reduced labor hours and reclaimed uptime.

Enhanced Operational Safety

With no rotating parts or pinch points, the Slidler is approved for use without guards and significantly reduces personnel exposure during operation and maintenance.

Minimized Maintenance Overhead

Eliminate the need for constant lubrication and inspection of failing rollers while benefiting from a patented, tool-free cartridge replacement system.

Asset Protection

A stable, UHMW-PE sliding surface provides consistent belt support, preventing the premature belt and component wear caused by seized traditional idlers.

How It Works

Slidler replaces traditional idler rollers with solid polymer cartridges mounted to a precision steel frame.

No moving parts.

No bearings to fail.

No pinch-points.

Result: 2–5× longer belt and component life, zero idler maintenance, and safer operation.

See How The Slidler is Being Used in Your Industry

The NovaGlide Slidler is engineered to perform in the world’s most demanding environments.

Mining & Aggregates

High-impact support and abrasive material handling.

Sawmills & Pulp and Paper

Debris-resistant configurations and long-term reliability.

Raw Food Processing

FDA-approved materials designed for hygiene and durability.

Power & Chemical Processing

Anti-static options and extreme temperature resilience from -80°C to 220°C.

Key Benefits

Enhanced Safety

No exposed rotating parts — eliminates pinch-point hazards and removes need for safety guards.

Lower Total Cost & Higher ROI

Longer wear life, minimal upkeep, faster change-outs. Payback in months, not years.

Reduced Downtime & Maintenance

Quick cartridge change-out in minutes. No seized rollers. No weekly greasing.

Technical Specifications

Belt Widths: 18″-60″ (457 mm-1524 mm)

Belt Speeds: Up to 600 FPM (180 m/min)

Operating Temperature: -80°C to +220°C (-112°F to 425°F)

Cartridge Options: Anti-static, FDA-compliant

Click to expand images below ↓

Validate Performance with a Pilot Installation

We recommend beginning with a small-scale pilot installation on your most problematic conveyor run.

This allows your team to quantify improvements in labor, safety, and reliability under real-world conditions before a full-scale rollout.

Proven Results

MINING:

“$198K ROI over 5 years.”

PAPER MILL:

“$22K ROI after 3 years.”

WINTER CONVEYORS:

“$198K ROI over 5 years.”

PEAT INDUSTRY:

“$100K+ savings in 3 years; $4K/mo downtime avoided.”

Contact us

info@novaglide.ca (902) 229-2447

Our location

201-3600 Kempt Road

Halifax, Nova Scotia

Canada B3K 4X8